Burr-free Drill / End Mill Router for Composites

Burr edges and delamination inhibited by special design of tool geometry

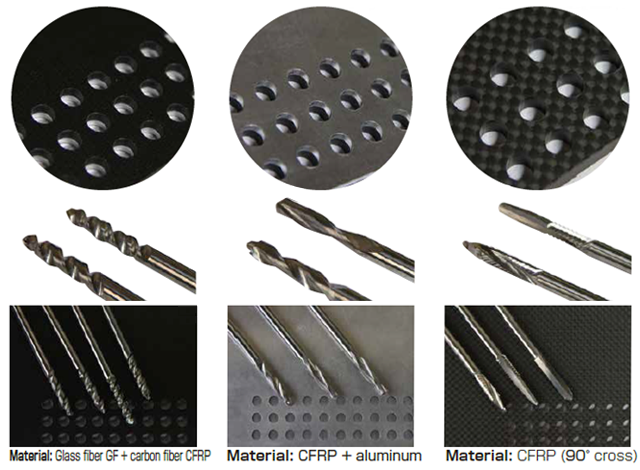

Applications

Carbon Fiber Composites, Glass Fiber Composites*, Honeycomb Composites

Multi-layer Composites of CFRP, GFRP, and Metal (Aluminum, Titanium, Copper, etc.)

*Includes difficult-to-cut glass fibers such as Aramid and Kevlar.

Applicable Industries – Aerospace, Automobiles, Robots, Machinery

In various fields where composites are used, special bits improve the processes of machining through to assembly preparation.

Issues in Machining of Composites

Poor cutting capability on carbon and glass fibers

Burr edges occur and deburring is needed

Delamination causes low production yield

Machining speed cannot be increased due to heavy wear

Special Bit Geometry for Composites

Cuts fibers in composites clean

Deburring not needed

Improved machining yield. Reduced tool use

Suitable tool choice ensures fast machining speeds.

For decades, Sanko Hamono’s advanced tool line-up has not been only for metalworking but also for woodworking. Just like wood, advanced composites contain lots of fibers. “Which type of geometry can cut fibers clean?”, “How smooth can a tool cut material?” The answers to these questions we can provide are our technical advantage. We pursue the best cutting tool design for the most advanced materials.